PRECISION MACHINING CAPABILITIES

World Class Precision CNC Machining & Electro-Mechanical Assembly

OUR EXTENSIVE CAPABILITIES

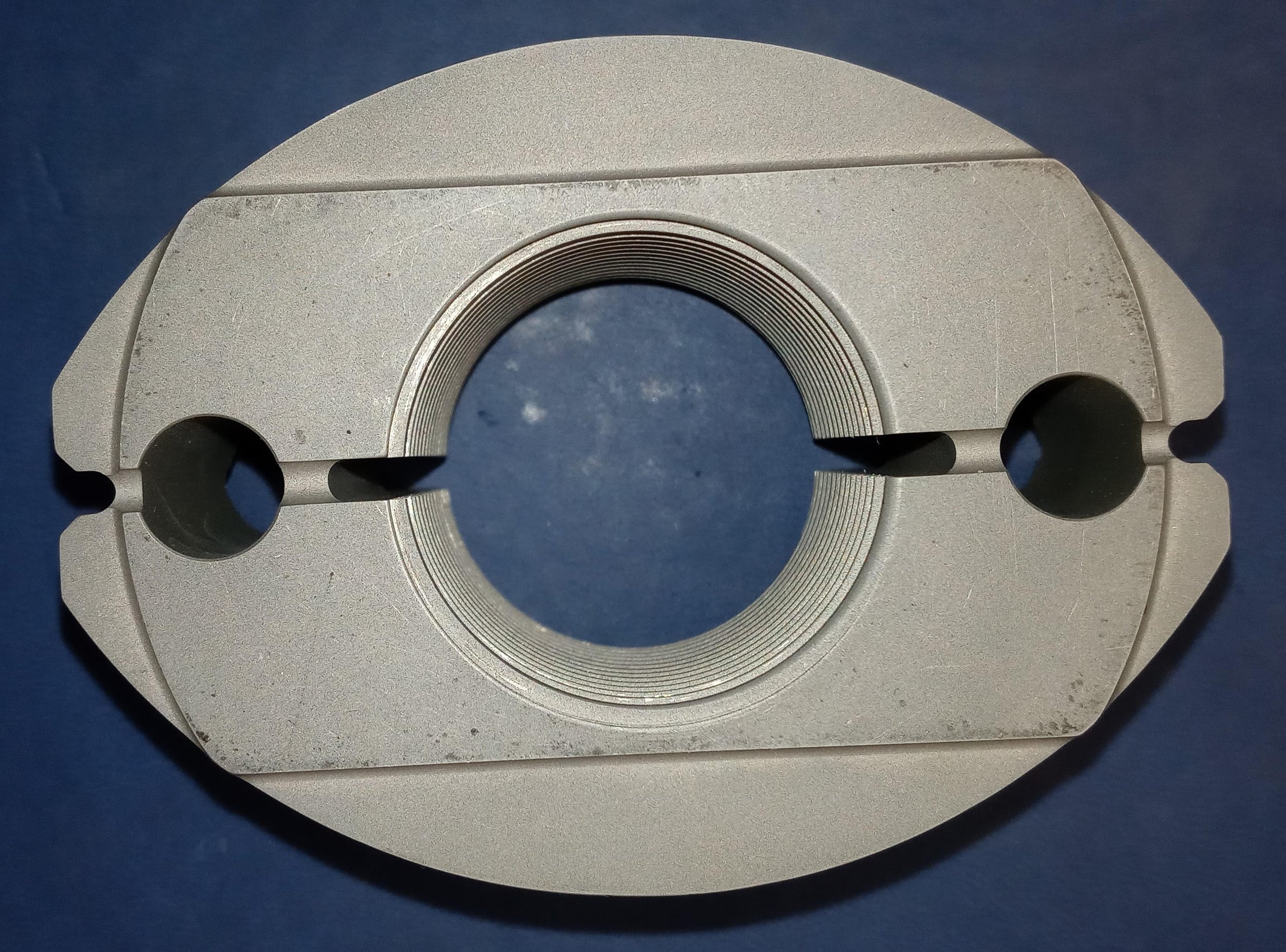

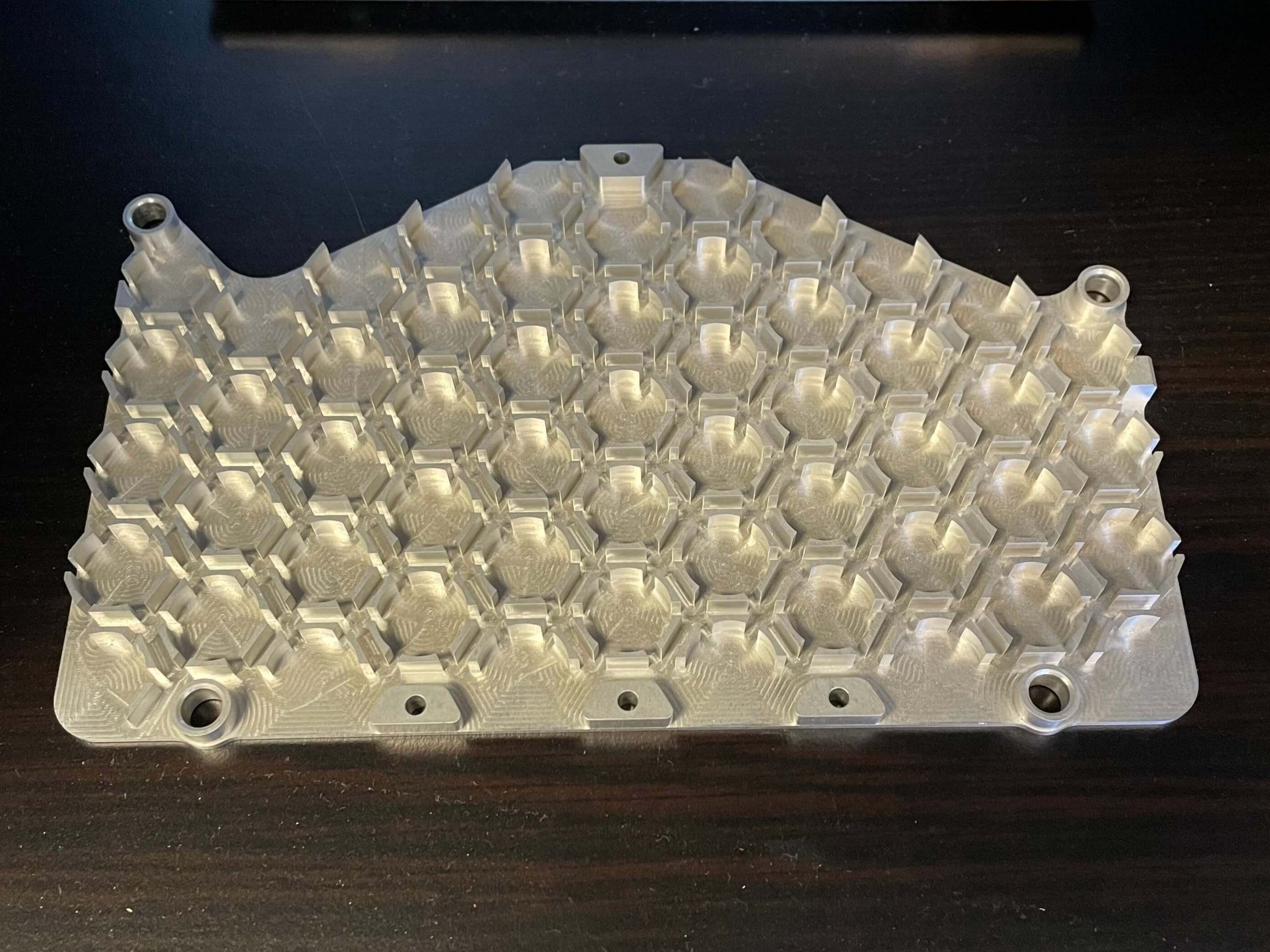

We are constantly installing more diversified machinery and modifying work cells to completely machine parts with minimal handling. Our automatic screw machine turning capacity is .060" to 2-5/8" diameter, CNC turning from .062" to 8" diameter, 5-axis CNC milling capacity is up to 20" x 25" x 60".

Although we have precision as small as .062, we can also turn blanks up to 8" diameter, or mill castings up to 20" x 25". This enables us to meet a wide range of product fulfillment. For quality assurance, we use ISO 10012-1 traceable calibrated inspection tools and a real-time computerized SPC system. These machine sizes cover the most common product size ranges and adapt to cut, turn, bore, thread, mill, drill, ream, tap, slot, grind, hone, lap, or burnish almost any precision part. All equipment is calibrated and traceable to ISO 10012-1. Real-time networked SPC is integrated extensively.

We are able to provide the following services and capabilities:

➢ Turning

➢ Milling

➢ Screw Machining

➢ Threading

➢ Cylindrical Grinding

➢ Centerless Grinding

➢ Laser Cutting

➢ EDM

➢ Slotting

➢ Drilling

➢ Honing

➢ Tapping

➢ CNC Grinding

➢ Assembly

➢ Waterjet

➢ Welding

Facilities (sq ft)

50,000 Buildings (5 total)

38,000 Manufacturing

5,000 General Offices

5,000 Shipping & receiving

1,700 Inspection & Quality Control

300 Chemical Storage

Turning

Screw Machines: single- and multi-spindle

CNC Lathes: 2- & 4-axis; Driven tools Y-axis

CNC Swiss screw machines

Competitive Advantage

Registered Quality System (AS9100 & ISO9001)

Over 50 Years Operating History

SBA Small Business & HUBzone Certified Company

Proven Management Staff

Integrated And Vast Supply Chain

Short Lead Time Prototypes

Extremely Responsive to Customer Needs

Milling

3-, 4-, & 5-Axis machines

Trunnion Table 5-Axis, 5-Sided Machining

CNC Pallet Changes; Pallet Pools

Vertical & Horizontal Mills

Grinding & Honing

CNC OD & Centerless Grinding

Honing & Sunnen Hones

Quality System & Approvals

ITAR, EAR, DFARS, SAM, EXOSTAR Registered

DLA Troop Support Class 2 Threaded Fastener

Qualified

Source Inspection Delegated (Dock-to-Stock)

Statistical Process Control Network

Automated Coordinate Measuring Machines (CMM)

OASIS and Keyence Shadow Optical Measuring Devices

Equipment

50 Automatic Screw Machines

7 Swiss CNC

50 CNC Turning

48 CNC Milling

90 Secondary & Shop Support

11 Production Grinders / Hones

Full 2nd Op and Assembly Capabilities

TIG Welding, Deburring, Polishing, Tumbling,

Riveting, Helicoils, Press Bushings, amongst others

MATERIALS

Boasting a wide range of material capabilities